Skrevet af: Flemming Vejsnæs

FORMIC ACID 2 : KRÄMER BOARDS

KRÅMER (WOOD-FIBRE) BOARDS ARE VERY EFFECTIVE AND EASY TO USE.

The most commonly used varroa treatment method in Denmark is that using Kramer boards ( these are soft , absorbent wood fibre boards).

MAKING THE BOARDS

One can either make these boards oneself or do so together with other members of the association.

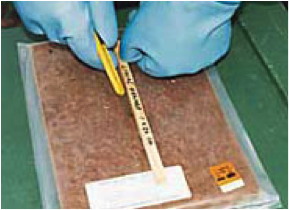

Soft wood fibre boards are used., cut to sizes of 17 X 24.5 X 1 cm, and inserted into acid resistant plastic bags. 250 ml. 85% formic acid soln. is then poured into the bag, which is then sealed with tape or ideally with a double welding using a welding apparatus for freezer bags.

SAFETY

Formic acid is corrosive and protective wear is advised ( see previous article)

THE PLACEMENT OF BOARDS

These boards should be placed so that they cover the whole frame area. A vaporizing area can be created by placing an empty super over the boards. The boards themselves should be placed on 2 cm. high laths placed on top of the frames. The vaporizing space provides for a more even distribution of the formic acid down through the frames.A crown board can be placed on the super.

USING THE BOARDS

For beekeepers who do not bring their bees to the heather, the boards should be used immediately after the first portion of winter fodder has been given, after the honey harvest. This is normally at the beginning of August. The boards should remain in place for 7 – 10 days and they can be used again if they have not released more than 100 grms of formic acid. Otherwise they can be refilled. The colony should be given the remainder of its winter fodder. The boards should be kept in a closed plastic bucket and thereafter placed on the hive again for 14 – 21 days, around the middle of September.

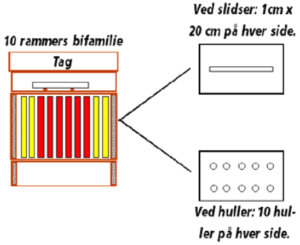

SLITS OR HOLES

One can either cut slits or make holes in the covering plastic of the boards in order to facilitate vaporization. Holes should be made in the ratio of 4 cm2 per frame. This means that for 10 frames an opening of 40 cm 2 should be used, to be cut out on both sides of the board, and which is the equivalent of a slit of 1 X 20 cm. In high outdoor temperatures the size of the opening can be reduced by 25%.

Our experience points towards using holes which gives the most even distribution, while with slits the danger is that the plastic can be pressed out to the sides and the opening thus becomes larger, and will give a greater vaporisation than desired.

A 16 mm hollow punch (can be bought at a hardware) can be used to make holes with, and this gives an opening of 2 cm2 . One hole of this size is needed per frame. Therefore, for ten frames ten holes in all are needed, to be made on either side of the board. With very high outdoor temperatures in the course of an early treatment, the area of opening, whether it be slits or holes, can be reduced by 25%.

TOO EXPLOSIVE A VAPORIZATION

Always use a cool board under treatment, as this provides for a slower vaporization. On warm days it is recommended to wait until evening before inserting the boards.

CHECKING THE VAPORIZATION

It is a good idea to carry out a check on the extent of vaporization by weighing the board before and after use. A reliable indication that the board is working satisfactorily is when 10 grm. of formic acid has evaporated daily. Besides, one can also check whether the board can be reused or not, by calculating if it has lost more than 100 grm. formic acid.